Hypericon / Technology / Mycelium

Mycelium

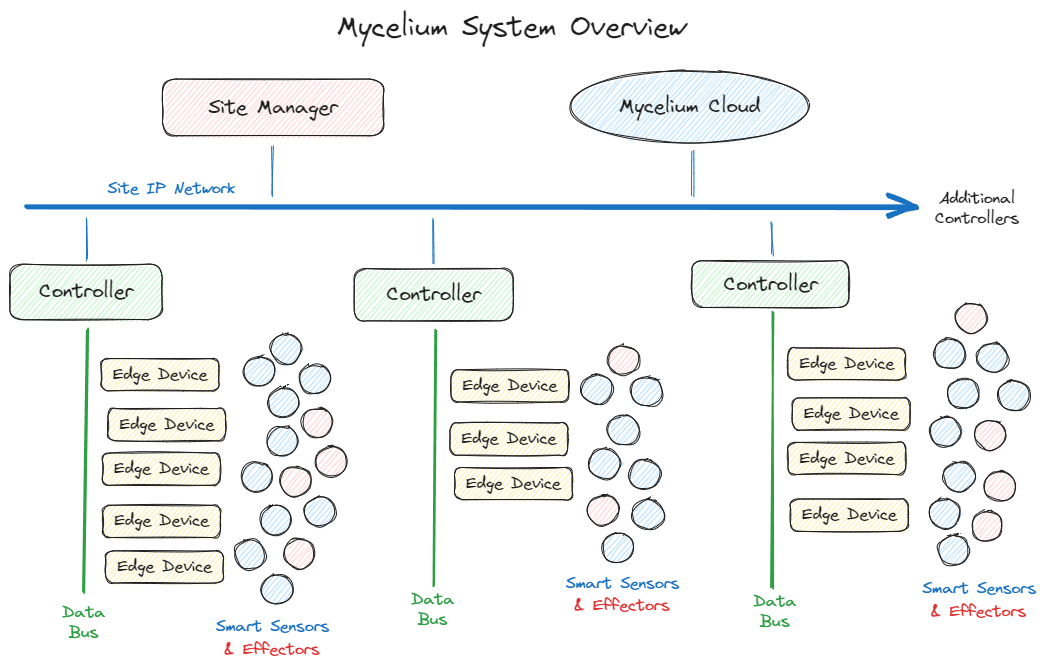

Mycelium is a complete solution of integrated technologies to manage specialised bio-cultivation systems.

Mycelium can be used for a range of bio-cultivation applications, including hydroponics, aquaculture, algae & moss cultivation, nitrate management, air quality management, and more.

Mycelium Controller

The Mycelium Controller is the central hub of our system, acting as the "brain" that manages growth in various Biocells. It processes sensor data like temperature and pH, and sends instructions to connected devices like pumps and lights.

The Controller communicates with smart Edge Devices via the Mycelium Data Bus. These Edge Devices then connect to the sensors and effectors. The Controller not only manages this Data Bus but also discovers and configures Edge Devices. It downloads calibration data from the Mycelium Cloud for each sensor and sends it to the right Edge Device.

The operator defines Runtime Protocols which the Controller uses for configuration. Each Controller can run multiple Protocols for quick prototyping and experimentation. While running a Protocol, it reports execution status and sensor readings to operators via the Site Manager and Mycelium Cloud.

For convenience in labs, the Controller has a touch screen. This allows operators to check sensor data, manually control effectors, confirm experiment steps, manage Protocols, and more.

Mycelium Data Bus

The Mycelium Data Bus links Edge Devices to a Mycelium Controller. Its network protocol auto-detects connected devices, simplifying setup and allowing quick reconfiguration and hardware hot-swapping.

A Data Bus can connect up to 250 devices to a Controller, offering flexibility in system topologies. It can connect devices up to 40 metres away, suitable for large labs or industrial settings. For more range, an IP adapter can extend this to 100 metres, and a LoRa adapter can reach over 1 kilometre.

Built on CAN bus, the Mycelium Data Bus combines Mycelium-specific features with reliable messaging technology.

Edge Devices

Mycelium Edge Devices link with Smart Sensors and Effectors to manage growth in a Biocell. They can have a specific role, like controlling a Light Engine or liquid ion probes, or be responsible for all devices in a Biocell.

Edge Devices connect to a Mycelium Controller via the Mycelium Data Bus. This allows for easy swapping in production and reconfiguration for lab experiments.

Edge Devices can take complex measurements using multiple sensors. This is helpful when the reading depends on the state of connected Effectors. It allows the device to provide accurate readings directly, saving time in processing experiment results.

Smart Sensors & Effectors

Our Smart Sensors and Effectors are reliable and high-performing, thanks to thorough testing and verification. Each device is unique, supporting precise calibration and clear tracking.

Mycelium Cloud provides calibration data, which the Mycelium Controller applies automatically. This removes the need for manual calibration, minimises error, and is ideal for quick equipment changes in labs and easy hardware replacement during maintenance.

Runtime Protocols

Mycelium Controllers use Runtime Protocols to manage bio-cultivation within Biocells. Protocols guide the Controller in issuing commands and collecting sensor data. They can be tailored to specific experiments or installations, with options for set conditions in lab settings or continuous running for production.

Protocols also identify the required Edge Devices and Biocells, along with their connected Sensors and Effectors. This makes hardware reuse and various topologies possible.

Controllers can only execute one Protocol at a time, but they can store a library of Protocols for easy switching.

The Protocol Editor is a user-friendly tool for defining and deploying new Protocols to Controllers over the local network.

Site Manager

Site Manager is a versatile tool for managing Mycelium Controllers, whether you're handling a few in a lab or hundreds in various locations. It grants operators a comprehensive view and control over all active Protocols. Operators can pause, resume, or terminate Protocols, allowing for hands-on interaction during experiments and quick response in emergencies. Additionally, Site Manager offers real-time updates from every smart sensor and the latest instructions sent to each output, keeping you informed of any alerts or notifications from the Controllers.

Mycelium Cloud

Mycelium Cloud serves as a hub for data and connectivity in the Mycelium system. It stores important data like hardware details, sensor readings, and test results. This ensures reliable operation and trustworthy experiment results.

The Cloud also offers tools for analysing sensor data and gives insights into your Runtime Protocols' performance. With real-time alerts and a central connection point for system components, you're always up-to-date on your system's status.

Mycelium Hardware Lifecycle

Mycelium hardware, including Edge Devices and a variety of Sensors and Effectors, is meticulously tracked throughout its lifecycle for accuracy and auditing purposes.

1. Manufacture

Mycelium's hardware is primarily produced in-house for quality control and consistency. For flexibility, we also support selected third-party sensors through our Smart ID Connector. This device allows our Edge Devices to interact with other hardware, retrieving up-to-date calibration data from the Mycelium Cloud.

2. Testing & Calibration

Post-manufacture, the hardware undergoes thorough testing and calibration. Each device's unique ID is registered in the Mycelium Cloud for efficient management. All test results and calibration data are stored in the cloud to ensure accuracy and maintenance efficiency.

3. Deployment

Upon deployment, the Controller auto-detects and identifies all devices, downloading the latest calibration data from the Mycelium Cloud. It continuously monitors the hardware, raising alerts for recalibration, servicing needs, or errors, ensuring a smooth and reliable operation.

4. Service & Maintenance

Scheduled performance verification and calibration are performed at Mycelium locations or authorised service centres. These centres use Mycelium's systems for accurate verification and may provide field-replaceable unit (FRU) replacement if required.

5. Refurbishment & Recycling

Mycelium adopts a sustainable approach to hardware management. Hardware is refurbished where possible, or responsibly recycled if beyond repair. Replacement hardware is hot-swapped in production environments with new calibration data automatically applied, reducing downtime and complexity.